Friday, December 26, 2014

Christmas at the Summit

On Christmas Day I set the last piece of subroadbed in place at the top of the helix which, in turn, fixed the highest point on the mainline. The height at the summit is 68 1/2 inches above the floor. Here's a picture - decorated for the occasion with a department store bristle-brush tree.

The initial planned altitude at this point was to be a bit higher, but as the two ends of the railroad approached each other, it became apparent that the height difference between the two ends was larger than planned. Therefore I reduced the grade on the last part of the upper turn of the helix in partial compensation. In fact. the clearance between the decks of the helix at the point of the sign is only 4 3/4 inches vs. the NMRA recommendation of 5 1/2 inches, which I maintained almost everywhere else.

As I don't intend to run double stacks or tri-level auto racks since they are out of my time period, this should not be much of a problem.

Another thing struck me today. This track arrangement reminds me of the three-level railroad crossing in Richmond, Virginia; which I visited earlier this year. Any similarity is unintentional, however. Here's a couple of pictures of the crossing in Richmond.

There is a canal below the crossing too, just to make this a really unique site. Today the area around the crossing is in a park. Unfortunately, all three tracks are not active as the lowest track, now owned by Norfolk Southern, ends just beyond the crossing. The upper two tracks are in daily use. Technically, though, since the grade-level track does still pass beneath, it's still a triple crossing.

Back on my layout, the lower two levels will be covered and out of sight. And, no, I'm not going to alter the plan (already did that too many times) to make this into a scenic feature!

Sunday, December 21, 2014

Fall Clinics

This fall I have been privileged to present a number of my clinics at a couple of model railroad conventions. On Sept. 19 & 20 I was at the O Scale National in Indianapolis and I presented three clinics: 3D Printing for Model Railroaders; Microcontrollers for Model Railroaders and Photo Backdrops Made Easy. The 3D Printing clinic was SRO and I gave an encore presentation on the following day. The hotlinks embedded above will take you to copies of the slides for each clinic.

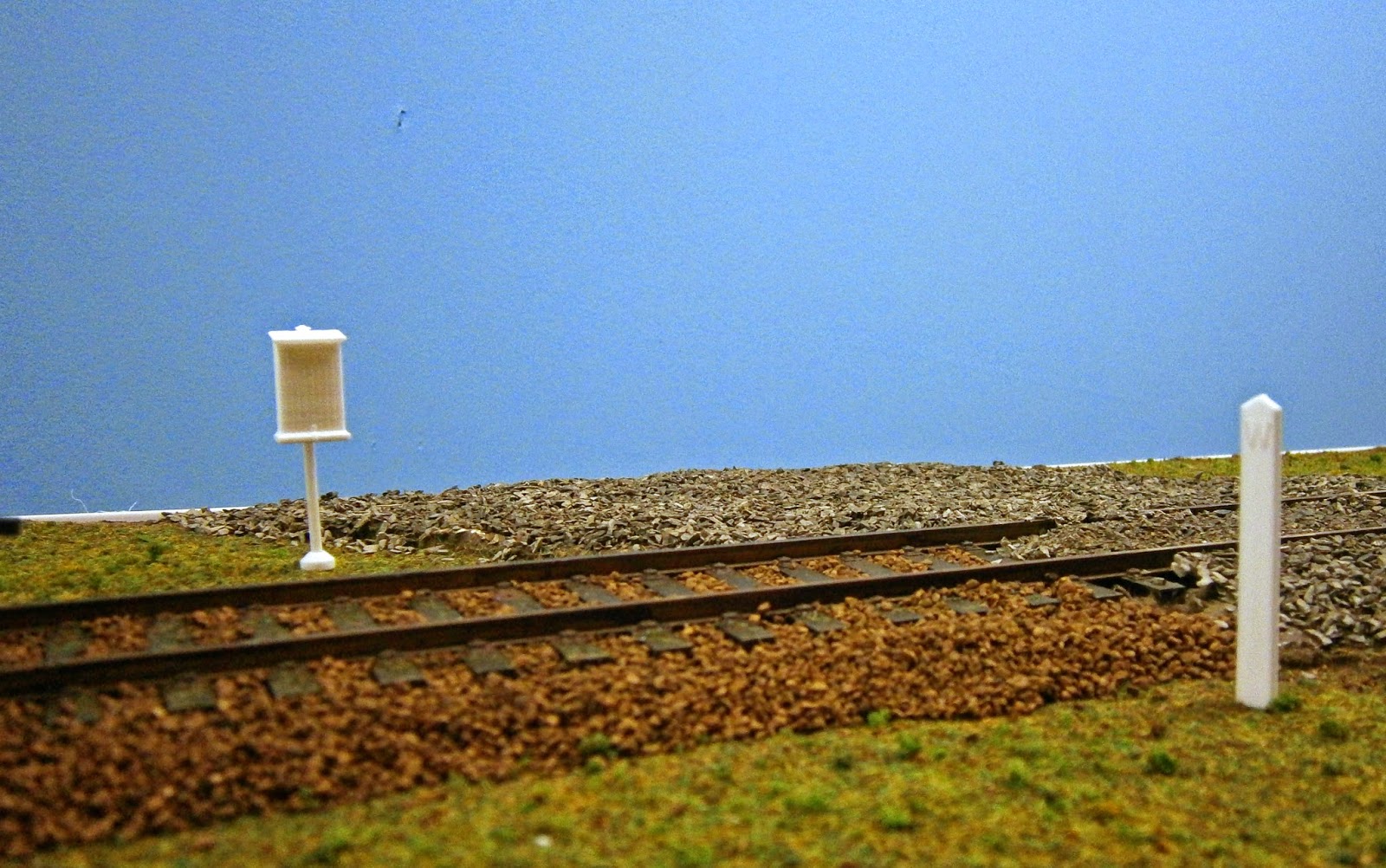

Here are pictures of the diorama that I built for the 3D printing clinic. Everything that you see in white on the diorama is a 3D print; in O scale of course. The concrete telephone booth is a resin casting from a 3D printed master to illustrate the use of 3D prints as casting masters.

You should be able to spot B&O and WM whistle posts, B&O and PRR telephone boxes; a B&O dwarf CPL signal; a PRR catenary post. The 2 critter bodies fit over an O scale Atlas switcher mechanism from the 1970’s that’s still readily available. The cab-only print turns the switcher into an Fn2 critter and the full body print is a freelance design that could be a diesel or it could be electric with the addition of a pantograph or a trolley pole. I also had various 3D printed items that I passed around at the clinic.

The Microcontrollers for Model Railroading clinic is an expansion of the LaunchPad for Model Railroading clinic that I gave last year. The new clinic includes microcontroller products from a number of additional manufacturers. The number of microcontroller products has exploded in the last couple of years with different manufacturers offering a bewildering array of features on their products. The clinic provides a quick overview of some of them.

I presented 2 clinics on Oct. 19 at the MER NMRA regional convention in Hagerstown, MD. 3D Printing for Model Railroaders was again SRO. The other clinic was Photo Backdrops, which attracted some non-model railroader spouses.

At all of my clinics I distributed a disk containing all 3 clinics, my 2 videos on Photo Backdrops plus a sample panoramic photo that attendees could practice on. You can find my videos here and here. I had exactly enough disks for all of the attendees. However, if you want a disk, I will burn one for you if you send me a self-addressed stamped envelope to mail the disk back to you.

Next year I’m thinking of adding a fourth clinic – Fun With LEDs. This will be an expansion of the Fun With LEDs entries on this blog of a couple of years back with a working diorama showcasing uses for LEDs.

So if you would like for me to present at your convention in 2015, let me know and we’ll see if we can work it out.

Saturday, December 20, 2014

A Job Too Long Postponed

I've recently completed some work on

the layout that I have been putting off for years. When I built the

lower hidden staging (which was not in my original plan) I had to put

a curved crossover between the inbound and outbound tracks to

facilitate routing trains to/from any track of the five in staging. The

crossover was hand-built before I had the Fast Track fixtures and

worked out a method of laying curved turnouts in the regular straight

fixture. The crossover is fine with most rolling stock. But after I

had laid it, I discovered that Weaver diesels would cause one of the

two turnouts to short out. Now, if you know modern O scale, Weaver

diesels are staples and unavoidable. So it had to be fixed.

Preliminary investigation indicated

that the back of the wheelsets were shorting out on the closure

rails. Fixing this would require resetting the throwbar on the

offending turnout, which was already laid in place. Not a job I was

looking forward to. All to moreso because the crossover is located

in an area that I can reach to lay it; but to do detail work on it in

place, I would have to stand on a step stool and then bend over –

an invitation to a backache. So I put it off with the

rationalization that I did not have to fix this until the mainline

was ready to be built above. Of course, the fact that this turnout

needed to be fixed before extending the mainline became an impediment

to finishing the mainline. Pretty good exercise in circular logic,

no?

Well after nearly two years of little

progress on the layout (joblessness for most of '12 and being on

crutches for half of '13) I am in the process of making a maximum

effort to finish at least one track of the mainline. Therefore I had

to steel myself to fix this turnout and continue major track laying.

This photo shows the crossover; the offending turnout is the one on the right (Yes, that's a seriously wide tie spacing on the crossover - remember, this crossover is hidden and will not be seen).

Actually, absent the resulting backache and one additional problem, it wasn't as bad as I had been dreading. Repositioning the points at the throw bar did fix the shorting problem. Rechecking the entire turnout with the NMRA gauge revealed that there was a gauge problem at one of the wing/guard rails causing an ever so slight bump as trucks passed through the frog. Since this turnout will be buried under benchwork and track above, it had to be as bullet proof as possible.

Filing inside the flangeways to correct the check gauge resulted in the expected backache (3 weeks and fading at this point). The truck that you see in the picture has what has become my standard wheelsets - Intermountain O scale 33" wheels. Once the check gauge was to NMRA standards, this truck passed through without any bumps. In fact, with my finger on the truck, I can barely feel the frog passage.

I then tried the turnout with a six-wheel heavyweight passenger truck and - damn - the truck had a bounce going through. WTF? Back to the file, checking as I went. The turnout was to NMRA specs. Maybe, I thought, the longer truck required me to take it to the extreme wide limit of the NMRA range.

When I got the turnout to the maximum allowed by the gauge, the heavyweight truck still had a bounce. Fortunately, before I went below the NMRA standards I checked the heavyweight's wheels and, surprise, surprise, the back-to-back on the wheelsets failed - too narrow. I feel really dumb - this is not the first time I've used wheelsets that were out of gauge to build or test a turnout - driving me nuts in the process. I should have checked the truck before using it as a standard. I guess that my learning curve is a flat line.

The blue-green thing at the extreme right of the photo above is a servo with some sound dampening material stuck on it. This servo throws the problem turnout and it has been there almost since the turnout was laid. The other switch needed a servo before this area is covered over. Since these two turnouts are in a crossover and must always be thrown together, I had obtained some servo "Y" cables to connect both servos together so they would throw simultaneously.

Since both servos would move in the same direction (CW or CCW) the second servo would have to be mounted in the proper physical orientation to move the other throwbar in the opposite direction. I tried to figure this out analytically but too many variables (facing right or left; above or below the track, etc.) made my head hurt. I finally just fashioned a crank and held the servo in place while I threw the switch and empirically determined the proper location for the servo.

The next photo shows the final location and orientation.

This second servo is under the roadbed (the first servo is above the roadbed) and facing in the other direction to the first servo. My head would have though that two reversals of orientation would make the throws move in the same direction; not so (that's why I'm not a mechanical engineer).

The servo is glued to a bracket as is outlined in an earlier post in this blog (A Few Simple Solutions). The second bracket that you see is just there to protect the servo because it's located above the duck-under to my workbench.

With THAT job out of the way, the mainline could continue. I had cut sections of road bed to fit the three-track curve above this location a week or two before. The next few photos show the roadbed progressing on what will be "Graveyard Curve" on the Cranberry Grade.

The next photos show the crossover and why it had to be just so before the mainline could continue.

As I write this, the curve's sub roadbed is in place and I'm finishing sub roadbed at the top of the helix. Now the two ends-of-track are pointed at each other. There's a small matter of about 6 inches difference in vertical height in a run of about 14 feet - and the first time something is not as planned in 3rd Plan It. I have some re-figuring to do and probably will have to increase the grade through Graveyard Curve and the approach to Terra Alta, WV (top of the helix). By serendipity, that's exactly what the prototype had to do on the approach to Terra Alta.

Subscribe to:

Posts (Atom)